SB visits… Ellers Farm Distillery

By Rupert HohwielerThe Spirits Business swung by Ellers Farm to check up on Dutch Barn Vodka and the Yorkshire distillery’s upcoming English whisky.

Ellers Farm Distillery is located in Stamford Bridge (the village, not the football stadium), about a 30-minute drive from York in the North of England. The state-of-the-art distillery was once an old Dutch barn – hence the name of the vodka – and opened in 2022 after a multi-million-pound development, billing itself as the largest in the region.

While it produces gin, liqueurs and soon an English single malt whisky, its vodka is perhaps the best-known thanks to the involvement of Ricky Gervais, who became a co-owner in 2023.

While Gervais wasn’t present for our visit, co-founder Chris Fraser showed us around instead. He and the team were preparing (at the time of this visit) for Dutch Barn’s North America launch, putting the final touches to the upcoming whisky release and readying in general for upscaling and expansion. Among it all is a carefully mapped sustainability plan – a commitment to halve its carbon emissions by 2030 and reach net zero by 2040.

Fraser tells us the distillery is hoping to rely solely on renewable energy. The company could switch over and be a net zero operation by the end of the year, but getting past Scope 3 presents the trickiest hurdle and one that’s often out of the distillery’s control.

He explained: “All of our various scope admissions, and we report all of them, we know what we can do, and what will get us to Scope 1 net zero. Getting to full net zero which involves Scope 3, that’s really hard because you rely on everything from the bottle manufacturer becoming a net zero operator to replying to every input, down all the way to even choosing apples for our crop. It’s achievable, but you need to pick the right partners – that takes a long time.”

Dutch Barn Vodka

Fraser tells us the initial spark for his vodka came just over 10 years ago when he made cider using unpicked apples from a nearby orchard for an at-home distillation.

Fraser was training for Ironman (the long-distance triathlon), so making 350-litres of cider for one person wasn’t the best healthy drinking option – he somewhat sensibly chose vodka, lime and soda instead. He began playing around with distilling in a little pot ‘still’ (which is on display in the visitor’s centre), running it through five times to claim it was ‘five-times distilled’, but it wasn’t really vodka, as Dutch Barn’s now master distiller pointed out to him.

Fraser recalls: “I remember the first time Jamie [Baggott, Dutch Barn’s master distiller] came around to my place, I said, ‘oh yeah try that’ and he took one sniff and he just replied ‘nope…”

This, along with a sense that things could get a little dangerous at home, meant it was time to find a bigger space.

Ellers Farm has its own orchard where it grows apples for the vodka, the key to the Dutch Barn recipe, which we were unfortunately unable to see on our visit as the British weather was doing its thing.

The orchard is currently in phase one of growth and the plan is to have 20 acres around the distillery. “We’re creating a biodiversity offset – sort of like a little sanctuary area,” Fraser says.

Inside the distillery, Fraser talked us through its apple spirit. Observing the fermenter, he said the cider is given a kick of sugar first just to get the fermentation process going because “you want the juice to start growing almost immediately once it has been contained and mixed together.

“Essentially in about 72 hours, we’re trying to go from apple juice and into cider, coming out at a quite high alcohol content, at around 12% ABV.”

He notes the energy and water conservation systems that the distillery has in place to ensure high efficiency: “I can’t remember what the stat is, but we use like 98% of our processed water. There’s no runwater waste and behind the cider is primarily a massive heat exchanger.”

On apples, Fraser added: “We knew we could make a clean vodka with nothing in it but I don’t think that brings anything to a cocktail.”

“Whisky drinkers will drink their spirit neat, Tequila drinkers the same now, but most vodka is drunk either with a mixer or a cocktail. The highest bar for a vodka cocktail is a great Martini and that’s what we’re trying to be – and in a really dry Vodka Martini because the vodka is the real showcase of what you’re trying to do.

“There is some flavour there, and there is intentionally a smell, because when that turns up in a Martini, we want it to be there.”

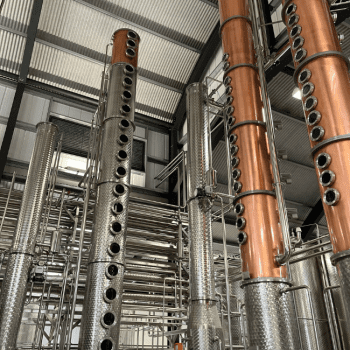

The vodka champions a smooth flavour and crystal-clear appearance, achieved by distilling the heated apple spirit at least 70 times through 70 distillation plates. The main columns have all been aptly-named: the 8.5m-tall Magic Mike as the stripping column, a 2,500-litre pot still called Granny Smith, Crystal (the de-meth column to reduce methanol levels, also a Breaking Bad reference) and then two rectification columns.

While the columns are split, the original idea was to place them all on top of each other, making it the tallest distilling column in Europe. The process is running all the time, 24/7, on one heat source, Fraser tells us, with the columns monitored every 20 minutes.

While Granny Smith and Magic Mike take care of distillation, Crystal’s job is to reduce the spirit’s methanol level to 1.5mg per 1,000 litres. Fraser says the distillery has relatively high methanol levels because it makes its vodka from fruit and to deal with the potato and food-based spirit that it also has. Crystal acts as a reverse distillation, he explains, essentially distilling the methanol, so the ethanol is a waste product from that.

For the rest of the process, the spirit is taken out the back of the distillery for a carbon treatment, which Fraser calls “quite unique” and which takes impurities out of the liquid. The filtration process uses two types of carbon designed to make one of – if not the – purest vodka on the market.

“We then let it settle, we tap off and then filter it 21 times. Then we let it rest and sit for a week essentially, to let everything calm down. That’s something our master distiller found just through time: if you rush it and go straight to the bottle, you end up with a vodka that is quite hot.”

As a hybrid vodka (Dutch Barn isn’t all apple), it also includes potato. For this, the team buys in a potato spirit and runs it through the steel, putting more copper on it, cleaning it up and then blending before bottling.

“We have potatoes in there because our goal is to make the best possible vodka in the world,” Fraser asserts. “The potato is about bringing balance and a little mouthfeel.

“Apple gives you a really clean, crisp vodka. Potato vodka, typically with 100% potato, is really creamy and tactile – and so just by bringing a little bit of that into the apples, we can create something really special. There’s very few who do that. When we designed Dutch Barn, we knew we’re going mostly apple, but we thought ‘what would elevate it?’”

Flavours

Fraser also showed us an oversized vapour chamber, 10 times the size of a regular one, where it puts in botanicals. The size is so they can put huge amounts of flavour into things they put through. With Mediterranean Citrus for example, the liquid is put in the chamber along with Mediterranean citruses (pomelo, lemon, lime and orange), and the fresh fruits are cooked through to create an “incredible” citrus distillate.

On why pomelo is used rather than grapefruit, Fraser says that “our distillers have always liked playing around with pomelo and it’s a nicer flavour in a spirit than grapefruit”.

“Pomelo is more grapefruit than grapefruit”, he adds for further emphasis….

Balinese Vanilla was the toughest for the team to pin down because when doing vanilla vodka properly, it’s not just the expensive part of it (though it is the most expensive to produce), it’s hard to get the actual vanilla to turn up naturally.

Of the process, he explains: “A huge amount of Balinese vanilla pods go into the pot and we create an overnight pot maceration – creating strong vanilla tea, if you will, and a really strong alcohol. We take the pods out and push that through the vapour chamber to give it a secondary hit of the vanilla – and that’s why it has such a natural vanilla flavour.”

He stresses that the process is complicated and it took many goes to get the flavour they wanted: “You just can’t get it [natural vanilla] in your spirit. When you put it through the still, the still will take it out, so getting it to go through the process and actually take the flavour that you want. I mean, when we did a couple of times, you would get the real sort of woodiness of the pods coming through, but the vanilla was left behind. We tried straight maceration, and yeah, with straight maceration… it can’t be clear.”

“You cannot have clear vanilla vodka if you’re going the natural route.”

Upcoming whisky

While Dutch Barn Vodka was discussed in detail, Fraser offered plenty of insight into the distillery’s upcoming whisky, too. The new make spirit, soon to be a single malt (November 2025 is the date, if all goes according to plan), was resting in ex-Bourbon barrels from Heaven Hill distillery on our visit, with a few Cognac barrels seen lying around as well as the team have an eye on experimentation.

The new make spirit has a name – ‘The Bairn’ (meaning child) – as it cannot legally be called a whisky until the end of the year, when it comes of age (three years). It won Gold at The World Whisky Masters 2023, so anticipation and expectation are both rather high for the debut whisky to say the least, with 1,000 bottles to be made available.

The distillery collaborates with T&R Theakston brewery in North Yorkshire to source its wash, the beery liquid that comes after yeast is added to start the fermentation.

“Theakston brings the beer essentially ready to be distilled here. They make the alcohol there, they do the fermentation process; Yorkshire-grown barley, Yorkshire malted barley, Yorkshire fermented barley, and then send it over here”, Fraser says of the process.

Most of the whisky was off-site being prepared for the end of the year. So present to us were the ones not going to cask as they were number one, at the top of the pile, and the other casks were all privately-owned ones sold last year as a founder’s release.

The first cask was laid down in August 2022.

Still time to buy one? “You have to buy off one of the members and I’m sure they will all charge a very high price”, Fraser said, setting honest expectations.

On the cask selection, he adds that “whisky is where we can have a bit more fun because you have more time”. Showing us a white Port cask, he says “we’re trying different finishes, just messing around, trying to see how they bring the spirit different elements.

“There’s a Cognac cask at the back. Apple brandy with our apple spirit. We’re trying different Bourbon casks – testing these and most of our casks are Heaven Hill. We’re trialling different charrings and then obviously the mash for each is different. They bring a slightly different characteristic to the whisky. We’re just playing around to see what works best, but we think Heaven Hill is pretty good – the liquid we’re getting on the whisky is pretty phenomenal.”

Regarding capacity, he says “we are running at the equivalent of probably 20,900 litres of alcohol a year. So we’re scaling up, so lots of excess capacity, but without much investment that can do about 1.2 million bottles per annum.

“With a bit of investment and some shift patterns, we can get over 2 million bottles a year, so we’re well short of that now.”

He’s hopeful in the long-term, though, that the amount can be doubled or tripled with off-site expansion.

It was then time to leave the technical stuff behind and head back to the visitor’s centre – which is a courtyard across from the production site – to the tasting room.

And having tried them all, and answering the all-important question of which was your favourite (‘I like them all’ was our safe response), it was time to wrap the show up.

We might have to return for a revisit, though, as with the new whisky around the corner and upcoming developments on the site, the distillery seems to be only just getting started.

Related news

SB visits… Volcan de mi Tierra