Bayou Rum: the American dream

Thanks to its abundant sugar production, Louisiana is the perfect place to make rum. Bayou master blender Reiniel Vicente explains the importance of the local terroir when it comes to making his spirits particularly special.

“Not many people know Louisiana is the fifth-largest producer of sugarcane in the world. It means Louisiana grows more sugarcane than all the Caribbean islands put together,” says Bayou Rum’s master blender, Reiniel Vicente.

Surrounded by all that sugarcane in a state famed for its spicy Cajun cooking and for hosting the biggest Mardi Gras party in the US, the lack of a home-grown, high-quality Louisiana rum was striking. But Bayou has put that right.

Vicente’s passion and experience in rum came from an early age. He was just 15 when he began working alongside his father, a distiller and master blender in the Dominican Republic who had previously worked in Cuba. He nailed the science of rum making with a degree in chemical engineering, and impressed the founders of Bayou Rum with his rum-making know-how and expertise. He was taken on in 2013, soon after the distillery started.

While so much rum is produced in industrial column stills, everything at Bayou is made in pot stills one batch at a time from the best, locally sourced molasses. Vicente calls the quality of the Louisiana sugarcane “amazing”, and says: “From the beginning we’ve had a partnership with MA Patout & Son – the oldest operating sugar mill in the USA, who’ve been going since 1825. We work very closely with them. They save the batches of molasses that are richer, with more fermentable sugar, and send them to us.”

Unlike most rum distillers, at Bayou the molasses is pasteurised to make sure it is as pure as can be before adding yeast that is specially cultivated in a lab from a strain of wild yeast found on the sugarcane. Fermentation is nice and slow. “Five days is the sweet spot where we really get the flavour profile we want,” Vicente explains. “It’s to create this natural sweetness.”

The second distillation in the pot still is where the essence of Bayou Rum is crafted by hand. “In the first hour of starting the still, we’ll be tasting the spirit every 10 minutes to define where to make the cut,” says Vicente. “Once we have the heart, the best spirits we can, we dilute it down to 60%-65% ABV and then, what’s very important is selecting the right casks.”

Bayou’s stablemate, Kentucky Owl Bourbon, provides all the wood required. It means “we’re getting the freshest Bourbon barrels, and a tremendous degree of control”, he says. “We know everything about them – the char, the level of toast, and the fact they were bought brand new.”

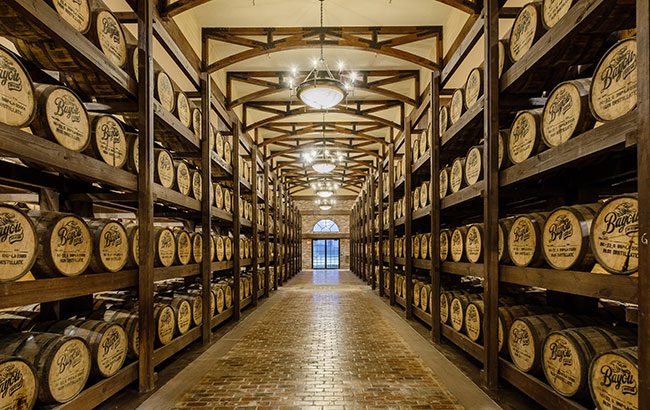

Then comes maturation, which, like the use of local sugarcane, stamps a real sense of provenance on the rum. With its heat and high humidity, Vicente describes the Louisiana climate as “extreme”, adding: “In the mornings it can be zero degrees, but in the afternoon, it can be 25˚C or 26˚C, and that creates a unique condition that you’re not going to find anywhere else. And we don’t control the temperatures or the humidity in our warehouse at all.”

Unique micro-climate

As a result, the angel’s share is quite something. At Bayou, the angels gulp down 6%-7% of the maturing stocks of rum each year, and because it is so humid the rate of evaporation of water is slightly above that of alcohol. This means that over four or five years, the filling strength of 60% ABV will have risen to around 61.5% ABV-62% ABV. According to Vicente, this “only happens in a few specific locations, like Louisiana. We are next to the Gulf, we have swamp lakes, also known as ‘bayous’, all around us, and the humidity is very high, so, it is a completely unique micro-climate.”

The purest expression of the rum is the unaged Bayou White, which shows the real spirit character on which the aged expressions build complexity through the wood.

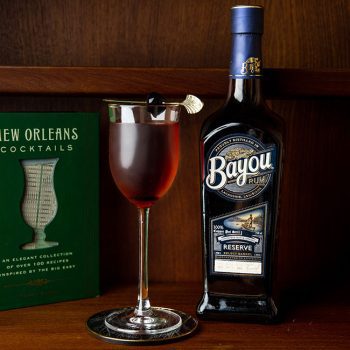

“Our Bayou Reserve uses a blend of barrels between two and five years old, which brings great smoothness to the spirits,” he explains. “It’s very easy to drink.” Above this sit Bayou’s Single Batch rums, which are treated to a particular type of barrel for their entire maturation, so, they are not ‘finishes’ in other words.

These single-batch rums are aged in rye whiskey barrels and red wine casks from Napa Valley. Three- and five-year-old expressions of the latter have been released, says Vicente. At the top of the range is the Bayou XO Mardi Gras, which spends a year in Pedro Ximénez Sherry casks after five years in Bourbon barrels.

The inspiration for Bayou Rum comes from a simple truth – that rum was the original American spirit. “We always say that the US has been producing rum for a very long time, in small batches,” Vicente explains.

Indeed, the roots of production go back to the Founding Fathers, who enjoyed the spirit as they forged the American Revolution. As president John Adams wrote in 1818: “I know not why we should blush to confess that molasses was an essential ingredient in American independence. Many great events have proceeded from much smaller causes.”

So, if the US has a rich history of distilling rum, the reasons are obvious to anyone in the Bayou of Louisiana. Here, you can find all the ingredients needed, from its steamy, sultry climate that is made for maturing smooth rums, to the abundance and quality of the raw material.

“Half the production of sugarcane in the US comes from our backyard,” says Vicente. “We’re about making high-end, top-quality rum, and we want to show the world that Louisiana has a lot to offer in this spirit. With its great quality it brings a whole new perspective on rum production.”

Related news

DropWorks founder on rethinking rum