This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

The big interview: Dariusz Plazewski, Bimber Distillery

Having made a success of his English whisky distillery, Bimber, Dariusz Plazewski is planning on expanding to the spirit’s heartland – Scotland. His new venture, Dunphail, will be in Speyside, and he has ambitious plans for it. Melita Kiely reports.

*This feature was originally published in the February 2022 issue of The Spirits Business magazine.

Distilling is in Dariusz Plazewski’s blood; his family has been making moonshine for generations in his native Poland. Watching his father and grandfather in action sparked curiosity in Plazewski, who also dabbled in brewing and making wine. He moved to the UK 20 years ago looking for “something new; an adventure”.

Plazewski put down roots in London, and originally put into practice his passion for design with a successful career in construction and property development. But as the craft distilling movement gathered momentum in the UK, his interest was piqued.

“I watched small producers starting to pop up, but mainly with gin,” he says. But his love for whisky was growing. “I visited so many Scotch distilleries, as many as possible, and just kind of fell in love. And I soon realised that it would be good to open a distillery in the future, and I started searching. I was so inspired by Scotland.”

A daunting category

However, the magnitude of the Scotch whisky category seemed daunting for a small producer like Plazewski.

“There were about 140 distilleries at that time, right, so I thought I’m not ready; I’m not ready for Scotland, it has become too wellestablished,” Plazewski recalls. “But London and England, we didn’t really have many distilleries. At the time when I started there were just two or three whisky distilleries, and nothing really in London. So from the research, I thought England needs some good craft whisky.”

In 2015, Plazewski turned his dream into reality with the launch of London-based Bimber Distillery – complete with all the traditional methods he valued so highly. Bimber, which means ‘moonshine’ in Polish, sources its barley from a single farm. It is then floor-malted, hand-mashed and fermented slowly over seven days in the distillery’s wooden wash backs, which were hand-made at Bimber’s own cooperage. Bimber uses direct fire to heat its copper pot stills before the liquid is filled into casks. And each expression is blended and bottled onsite in London.

Plazewski is also Bimber’s master distiller, and filled the distillery’s first casks on 26 May 2015. Three years later, in September 2019, the producer released its first single malt whisky, aptly called The First. Comprising just 1,000 bottles, every one was snapped up within three hours.

“We’ve also got a very small visitor centre, so we do tours and tastings,” adds Plazewski, “but it’s very small in an industrial area. So we’re looking to expand now after six years of being in this space, and to build a bigger visitor centre.”

The uncertainty of the pandemic meant Plazewski had to “postpone everything”. As the UK recovers from the impact of Covid-19, Plazewski’s expansion plans should be realised this year, he reveals.

“We still need some funds – we’re talking to potential investors – but we’re nearly there,” he enthuses. The expansion will mean a major scale-up for Bimber’s production.

“At the moment, we make around 50,000 litres of alcohol a year, so ideally we’re looking to double the production to 100,000 litres,” Plazewski explains. “We already have a new still, which is waiting in a different warehouse. We actually can’t fit it into the old warehouse, but we’re waiting to install it in the new place. So we’re almost ready to go with everything. We also need to install an additional seven wash backs.”

While Plazewski hopes to be able to “store as much as possible onsite”, external warehouse space will still be needed. Currently, Bimber uses two sites in England to store some of its casks, one in Manchester and one near Coventry.

In Bimber’s early days, Plazewski toyed with white spirits, including vodka, gin and rum. “But it was really just an exercise, and we tried to generate some cash flow,” he explains. “We didn’t really concentrate too much on this because when we started making whisky, we only distilled three to four days a week. Before we released our whisky, we increased production to six days, and after that seven days a week. So we didn’t have any more capacity to produce any other product, and, to be honest, it was a commercial decision as well.”

Ultimately, Plazewski wants Bimber to be recognised as a dedicated whisky distillery. Other spirits are no longer on his radar, with the exception of a small gin order for the Asian market. “But production is very small, it’s just requests from our distributor in Asia,” Plazewski notes.

A new release

Bimber’s whiskies are available in 28 countries, including Germany, France, China, Taiwan, Singapore and Hong Kong. “We’re also in Canada, the US, South Africa, Nigeria, so we cover a lot, plenty of countries,” Plazewski adds. New markets are unlikely to join this year due to production restrictions, but a new release can be expected in 2022. “We’ve got our first peated whisky, which will be launched in the middle of the year,” he reveals. “This is a heavily peated malt – over 50 PPM [phenol parts per million].”

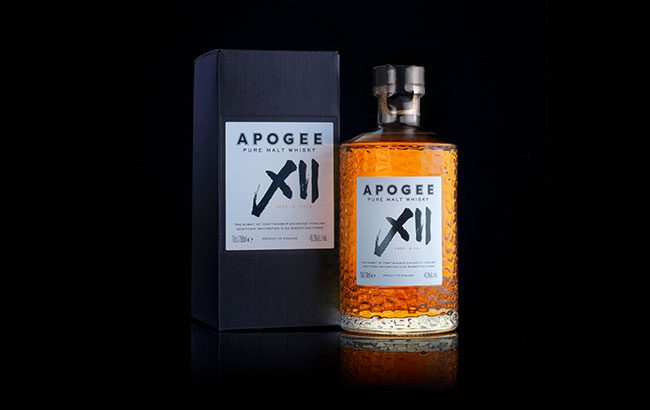

However, the distiller is in no hurry to put out a ‘core range’, so to speak. “First of all, we don’t have enough stock to do this, and secondly, we’re not rushing,” he insists. “We would like to have one product that is going to be available all the time, which we launched last year – our blended whisky, which is called Apogee XII.”

The liquid used to make Apogee XII is sourced from distilleries in the Highlands and Speyside regions in Scotland. Eventually, Plazewski says the blend could be brought in-house if all goes to plan with his next project: Dunphail Distillery in Scotland.

That’s one important benefit that came with the pandemic; it gave Plazewski space to focus on developing his Scotch whisky distillery plan. Details of the new facility came to light in March 2021 when a planning application was lodged with Moray Council. Approval was granted last July, and Plazewski is hopeful the site will be operational this year.

To construct the new facility – located on the Dunphail estate, south of Forres – an existing farm steading is being converted into a distillery with a projected capacity to produce 200,000 litres annually. “The pure reason I chose Dunphail is travel; I go to Scotland a lot and was visiting many places, and when I visited the site and the area, I basically fell in love,” Plazewski says. “I love Speyside whisky; it’s been my favourite for a long time. But it was also the perfect microclimate; it’s warmer than any other part of Scotland and quite dry as well, and we are protected by the mountains.”

Tradition and modernity

Much like Bimber, Plazewski aims to marry tradition and modernity through the distillery’s design. The distillery will house three pot stills (two wash stills and one spirit still), each with a 2,200-litre capacity. There will also be 12 wash backs, made from locally sourced Scottish douglas fir timber.

“I’ve learned a lot through Bimber, and I felt like I had enough insight to take what I learned in London, and build my dream in Scotland as well,” Plazewski explains. “I’ve developed a lot, being on a production site and making whisky, watching the process, how things impact flavour, from changing the barley, different seasons, fermentation – and you need to react to these changes. It’s been a great learning process.”

Dunphail Distillery will have its own floor-malting facility and a traditional kiln to process the locally sourced barley. Other features will include blending rooms, dunnage warehouse space, and a ‘cutting-edge’ visitor centre. Sustainable production will also be carefully considered, with plans to incorporate energy efficiency and water conservation. Ingredients and plastic-free packaging will be sourced as locally as possible – plus, Plazewski plans to grow a forest on the distillery grounds, and will plant a tree for every cask purchased.

“I always said when I do a distillery, it has to be done in a very traditional style,” Plazewski reiterates. “So again, we have to get the floor maltings, and have to have all the long fermentation, direct fire and all these processes in place to really achieve what we want to achieve. We are in Speyside but we want a really full-bodied but fruity spirit; I want some weight in the spirit. That’s what we’re looking for.”

There will, of course, be some limits to Plazewski’s production plans, and he’s open to the fact he may have to outsource some of the malted barley. “I’m working with Matt McKay, who is our director of whisky, and he’s going to help me create our style and our plan. We’ll see how much we can produce onsite and we might take a commercial decision that we’re only going to produce whisky from our floor maltings. But I haven’t made this decision yet; it’s one we’ll make soon,” he advises.

Together with McKay, Plazewski is keen to carve a “really old-fashioned” wood policy using “mainly hogsheads”. “We’re going to use quarter casks too, but mainly it’s going to hogsheads and some butts. So the wood policy will be completely different to Bimber, where we’re using mostly ex-Bourbon casks – that’s 80% of our production.”

If it all works out, construction should be finished later this year and production can then begin.

“But everything depends on the supply situation in the world because at the moment, the supply chain is really difficult, everything is taking much longer. We’re still hoping that by the end of this year we should be able to start production,” he notes.

Supply chain struggles

Like the rest of the industry – and other sectors worldwide – supply-chain struggles have hit the business hard.

“We’ve got six-month delays with our [Bimber] releases because we can’t get bottles,” Plazewski says as an example. “We can’t get corks. There are massive, massive delays, and massive impacts with shipments as well; it’s really difficult. Usually, even before Brexit, you were able to send a pallet to Europe in like three days, now it’s like three to four weeks.”

Unfortunately, Plazewski says the signs indicate it’s likely to be some time before the situation begins to improve. For now, the best he and his team can do is to plan ahead. “With all the extra customs checks and charges it’s difficult. Hopefully it won’t get any worse, but I don’t think it’s going to improve any time soon.”

For Bimber fans looking to get a first taste of what will be coming from Dunphail, there will be a long wait. Asked whether there will be any Scottish gins, vodkas or other spirits in the interim, similar to how he started off at Bimber, Plazewski states: “No: it was a mistake. If I were doing this again, I would never start doing any white spirit because it took a lot of energy and a lot of time. It wasn’t worth it commercially. So we’re not going to do this again at Dunphail. Dunphail is purely a whisky distillery, and we’re not going to produce any other spirit – just single malt whisky, and on the side we’re looking to launch an independent bottling programme.”

This will be sourced from casks around Scotland “and around the world if we can. The independent bottling will help to create some cash flow on the side,” Plazewski says. “But I’m a whisky geek – I’m all whisky and I want to stay purely whisky.”

With England and Scotland ticked off the bucket list, where’s next for Plazewski? Wales? Northern Ireland – or perhaps, across the pond? “After Dunphail, when we launch, I’m not going to do any more projects,” he insists. “I will have two distilleries, one in London and one in Scotland, and I want to enjoy them and share my love for whisky. I want to meet people, do lots of social events, tastings and divide my time between the two. After that, I think I will have achieved what I wanted to do.”